- Categories

- Ringfeder: Shaft Coupling & Shaft Locking

- Locking Assemblies

- Ringfeder TNF Flange Couplings

- Ringfeder Elastomer Jaw Couplings TNB

- RINGFEDER TNR Torsional Highflex Couplings

- TSCHAN TNM Flexible Couplings

- Ringfeder TNS Jaw Couplings

- Ringfeder TNZ Gear Couplings

- Ringfeder TNK Barrel Coupling

- Ringfeder TNT Safety Couplings

- Ringfeder TND Torsionally Rigid Disc Couplings

- Ringfeder GWB Metal Bellows Couplings For Encoder

- Servo-insert Couplings GWE RIngfeder

- Servo-Insert Couplings

- Nylon Sleeve Gear Coupling ECT Ringfeder

- Ringfeder Friction Spring

- Ringfeder HENFEL: Hydrodynamic Coupling

- KTR: Shaft Coupling & Shaft Locking

- Cross-morse: Puly, taper bushes, shaft Coupling

- JAC coupling : Gear couplings & Jaw coupling

- PT Couplings: Shaft Couplings

- KBK: Shaft Couplings & Safety Couplings

- 8. Martin couplings and Martin Elastome Rings

- 9. Fenner: Fenner Coupling, Fenner Belt

- 10Wichmann: Universal Joint Shafts

- 11. ITALGIUNTI: Cardan Shaft Coupling

- 12. Westcar: Brake & Fluid couplings

- TRANSFLUID: Fluid Couplings

- 13. Backstop Ringspann Couplings

- Max Dynamic Couplings

- FLENDER: Shaft Couplings

- 16. STIEBER: Freewheel, Sprag Clutch, Backstop

- 17. Hilger u.Kern: Tester Devices

- Helmke: Electric motor AC Germany

- I.Mak: Gear Motors & Gear Units

- Rathi-Lovejoy: Couplings

- Ringfeder: Shaft Coupling & Shaft Locking

ONLINE SUPPORT

0906 955 057

0906 955 057

PRODUCTS

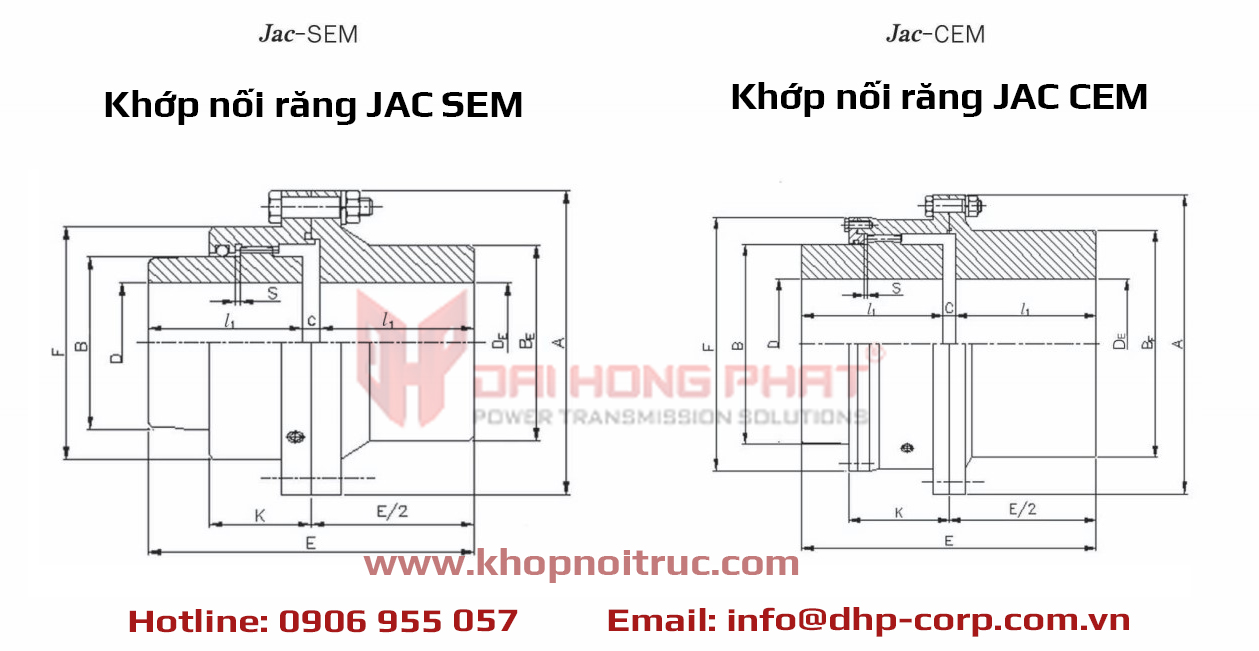

GEAR COUPLING JAC SEM - CEM

DESCRIPTION: Jac gear couplings SEM - CEM basically conformable to the "Gear Type Shaft Couplings" specified by KS(Korea Standard) and other standards are further engineered to have them display higher performance by making the best use of its year's technical experience and accumulated field experiment. With the cappacity of handling heavy load, Jac gear couplings are much smaller and lighter than any other couplings. Noise or vibration is hardly produced even in high speed operation.

SPECIFICATIONS

JAC Coupling Gear Coupling SEM-CEM

Jac gear couplings SEM - CEM basically conformable to the "Gear Type Shaft Couplings" specified by KS(Korea Standard) and other standards are further engineered to have them display higher performance by making the best use of its year's technical experience and accumulated field experiment. With the cappacity of handling heavy load, Jac gear couplings are much smaller and lighter than any other couplings. Noise or vibration is hardly produced even in high speed operation.

Catalogue Gear Coupling SEM-CEM

|

|

size out side A

|

torque rating (Nm)

|

max. speed (rpm)

|

dimensions(mm)

|

weight (kg)

|

|||||||||

|

bore D

|

bore DE

|

E

|

ℓ1

|

C

|

B

|

F

|

K

|

BE

|

S

|

||||

| (min/max) | (min/max) | ||||||||||||

|

SEM 112

|

80.3

|

4000

|

17 / 40

|

17 / 50

|

108

|

50

|

8

|

58

|

79

|

40

|

70

|

2

|

4.6

|

|

SEM 125

|

142

|

4000

|

22 / 50

|

22 / 56

|

134

|

63

|

8

|

70

|

92

|

43

|

80

|

2.5

|

6.7

|

|

SEM 140

|

205

|

4000

|

22 / 56

|

22 / 63

|

150

|

71

|

8

|

80

|

107

|

47

|

90

|

2.5

|

9.3

|

|

SEM 160

|

314

|

4000

|

22 / 65

|

22 / 75

|

170

|

80

|

10

|

95

|

120

|

52

|

105

|

3

|

14

|

|

SEM 180

|

482

|

4000

|

32 / 75

|

32 / 80

|

190

|

90

|

10

|

105

|

134

|

56

|

115

|

3

|

19

|

|

SEM 200

|

689

|

3810

|

32 / 85

|

32 / 95

|

210

|

100

|

10

|

120

|

149

|

61

|

135

|

3

|

26

|

|

SEM 224

|

1000

|

3410

|

42 / 100

|

42 / 105

|

236

|

112

|

12

|

145

|

174

|

65

|

150

|

4

|

38

|

|

SEM 250

|

1470

|

3050

|

42 / 115

|

42 / 125

|

262

|

125

|

12

|

165

|

200

|

74

|

180

|

4

|

56

|

|

SEM 280

|

2340

|

2720

|

42 / 135

|

42 / 150

|

294

|

140

|

14

|

190

|

224

|

82

|

210

|

4.5

|

83

|

|

SEM 315

|

3680

|

2420

|

100 / 160

|

100 / 180

|

356

|

170

|

16

|

225

|

260

|

98

|

250

|

5.5

|

135

|

|

SEM 355

|

5550

|

2150

|

125 / 180

|

125 / 200

|

396

|

190

|

16

|

250

|

288

|

108

|

275

|

5.5

|

184

|

|

SEM 400

|

7790

|

1900

|

140 / 200

|

140 / 236

|

418

|

200

|

18

|

285

|

329

|

114

|

325

|

6.5

|

261

|

|

CEM 450

|

11000

|

1690

|

140 / 205

|

140 / 225

|

418

|

200

|

18

|

290

|

372

|

151

|

320

|

5

|

304

|

|

CEM 500

|

16600

|

1520

|

170 / 236

|

170 / 270

|

494

|

236

|

22

|

335

|

424

|

168

|

380

|

6

|

453

|

|

CEM 560

|

25500

|

1360

|

190 / 275

|

190 / 305

|

552

|

265

|

22

|

385

|

472

|

187

|

430

|

6.5

|

664

|

|

CEM 630

|

42000

|

1210

|

224 / 325

|

224 / 355

|

658

|

315

|

28

|

455

|

544

|

213

|

500

|

8

|

1020

|

|

CEM 710

|

61200

|

1070

|

250 / 360

|

250 / 400

|

738

|

355

|

28

|

510

|

622

|

242

|

565

|

8.5

|

1460

|

|

CEM 800

|

87500

|

950

|

280 / 405

|

280 / 450

|

832

|

400

|

32

|

570

|

690

|

267

|

635

|

9.5

|

2090

|

|

CEM 900

|

125000

|

840

|

315 / 475

|

315 / 510

|

932

|

450

|

32

|

670

|

762

|

295

|

715

|

10.5

|

3020

|

|

CEM 1000

|

171000

|

760

|

355 / 510

|

355 / 570

|

1040

|

500

|

40

|

720

|

858

|

322

|

800

|

12

|

4130

|

|

CEM 1120

|

240000

|

682

|

400 / 600

|

400 / 640

|

1160

|

560

|

40

|

840

|

990

|

360

|

900

|

13

|

5970

|

|

CEM 1250

|

331000

|

610

|

500 / 710

|

500 / 800

|

1460

|

710

|

40

|

960

|

1126

|

399

|

1060

|

14

|

9820

|

| (Note) Coupling weight and GD2,without Bore machining | |||||||||||||

RELATED PRODUCTS